Saturday, 28 May 2011

Finecast - a review

So here it is, Citadel Finecast has been released and I have my hot little hands on a model for my current Warhammer project: A Dark Elf Repeater Bolt Thrower. Handily I have built several of these for various shops and individuals over the years in its metal incarnation so I can compare fairly easily.

At first glance, not a lot changed save that banner at the bottom and the slightly more obvious 12+ sticker. I gotta say I much prefer the look of the new clamshell packs for the smaller minis to the old blisters. Big improvement but that is by the by, lets crack this bad boy open and see what we have here!

First surprise was: Sprues? Really? Ok, cool. Second thought that struck was "my lord, flashtastic". A fiddle with the flash though showed it was paper thin and tore off like a stamp. Not a big deal. The material is something a little new, for all the cynics out there I had to hand a sample of Forgeworld resin and Privateer Press "plastic" to compare with and it is not really either of them. It is way more flexible than both of them. Easier to cut and shape than the Privateer Press stuff and doesn't have that greasy mold release feel of the Forgeworld. Then the third thought struck me:

What the hell? My crewman has a mangled foot! A real shame as this was my very first of these Finecast figures to get a broken one. Will wait to see if the odds were against this or whether it is a common occurance. As it happens the foot was too badly damaged to be easily saved. Grump, will keep you informed about how open GW customer service are to replacing these parts. I started clipping the components from the sprues and looking toward clean up.

Most of the mold lines seem to be these minor mold misalignments (try saying that three times drunk). On a metal model these would be disasterous and take forever to fix. On these figures, one pass with a sharp knife and a quick rub with a sanding stick.

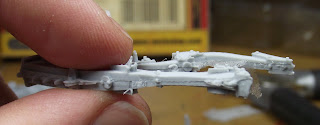

Then ran into the next problem: Warping. It was at this point that I had to remind myself that I was not comparing finecast to plastic. I was comparing it to metal. Metal warps too so it isn't such a hardship to deal with in the new material either. My heart did sink though as I was expecting to do the usual resin palava of hot water dips and reshaping followed by a cold water plunge to set. Unlike Forgeworld resin though this was able to be just bent back into shape. Nice surprise. Disapointing that you have to correct this at all but good that it is a fairly easy fix. Here it is after correction:

It is worth doing though as otherwise you will have some very odd looking parts as the next picture will demonstrate:

The parts really fly together with superglue. Believe me, I've made a lot of these in metal and they are a regal pain in the bum. This one was a doddle. It is true that we can forget pinning, these figures just don't need it. Unfortunately on the next parts I found the first real problems:

Terribly warped upper arm of the bow, I had to spend some time twisting and recarving this part with my knife. Mercifully I have the skills to do this, many do not. Then:

Voids. Really bad ones, I can handle a little bubble in the resin, you just dot it with superglue and sand it flat. Some of these clusters of bubbles had all but destroyed the part. I rescued them with carving or hiding them on underneath surfaces (in the case of the arrow) but these are pretty bad. I hope this is just a symptom of casting a new material being learned rather than a systemic problem. Time will tell. I suspect that Finecast just is not designed for war machines like this because as we are about to see, its real strength is the organics:

Now, I don't even like the crew miniatures for the bolt thrower much, I bought the model for the machine, but just look at the casting. The scroll and wrapped cloak in the inserts especially. Again comparing with the metals I have put together of this figure there is no contest. This is a much better medium for capturing those thin details, ignoring undercuts and allowing crisper edges to cloth. I imagine we will see a gradual shift into plastic for anything but character models as this will allow the resin material to shine and use the plastic for what it is best for.

So, lets sum up then, good points first:

1) Very light, very easy to stick together. The whole process including photography took just 40 minutes.

2) No need to wash or prepare beyond the normal removal of mold lines

3) Really crisp details

4) Easy to carve, cut and sand.

And then the not so good:

1) Broken componants, remains to be seen if a systemic problem or just bad luck.

2) Warping, although this is easier to solve than in metal or normal resin.

3) Bubbles, this is the real problem, until this is solved I think we will be doing a LOT of filling or exchanging parts.

4) Delicate, I hadn't touched on this but you cannot be heavy handed with these. Granted, this is a slender model and was designed to be moulded in metal but seriously. Keep clumsy people away from these and base them!

All in all, not too bad. Very disapointed about the breakage, worried about the bubbles but impressed by the potential especially when we start to see models designed to by cast in this material rather than metal recasts. I will keep you informed of my Finecast adventures, especially on the second bolt thrower (will it have identical problems? If so, that will be more concerning) and on the single miniatures that I feel this medium is designed for.

To finish off a final thought: I think on balance resin and metal are close in merits, both have virtues, both have serious flaws. Plastic is still the best material for modelling, especially in this day and age of CAD modelled tolerances and super fine detailing. Given the way that GW has been going we will see more and more plastic. I really think that this finecast material will simply fill a stop gap between the current situation and a time when virtually everything is plastic. Back to painting for the next post and the final Death Korps! Very exciting, till then:

TTFN

Subscribe to:

Post Comments (Atom)

Good balanced review. Thanks.

ReplyDeleteLinked up on my list of finecast reviews. Thanks for the pics and info. If you get a good piece people seem to really like the finecast minis but it seems like that good piece might be no better than 50-50.

ReplyDeleteWhat about the hand holding the scroll. Looks like he was shot with a 45 at close range.

ReplyDeleteGreat review thanks.

ReplyDeletePretty much what i expected though, being a collector of Forgeworld armies. The same problems now exsist between the two manufacturing companies ie: the Cons that you outlined here. These kind of problems are going to be a massive pain in the ass for the younger or less experienced modelers (as Forgeworlds stuff is only recomended for 'expert' models) Now the public at large are gonna have to become pretty proficient at tackling these problems as well.

A really great review. Unbiased and very informative. Thanks a bunch.

ReplyDeletea great review, i hadn't really looked at this at all until now, (kinda took my eye of the ball i guess) nice suprise though! Gun Grave could be right, some people will struggle with the extra work, but hey if nothing else it will mean people learning new skills and that's never a bad thing right?

ReplyDeletePersonally, I would have returned that model due to the many parts that seem to be ruined by bubbles and the Dark Elf's hand that looks like it has a problem with flesh eating bacteria. I've never had a miscast metal mini like that.

ReplyDeleteThey advertise those models as the best thing since the invention of sliced bread and if they command premium prices I want premium product. This doesn't really look like premium product, more like something that skipped QC.

Since in my country you actually have to fulfill what you say in the ads I assume they'll get a giant heap of returns.

Anonymous, I have had problems with metal models doing this, if you get a blocked air channel you get a weird crystalline cave. I am sending the pics to GW to get a replacement crewman and hopefully replacements for the missing voids. Will let you know what their customer service is like on this issue. On a general note, please at least stick a nickname in rather than anonymous.

ReplyDeleteI added a poll to my blog (http://twilight40k.blogspot.com) to log the qaulity of your finecast purchases so please come by and vote.

ReplyDeleteGreat impartial post.

ReplyDeleteI've been curious about the aftermath of the "finecast" and what the results would be.

I'm thinking you're right; the bubbles may just be a 'learning curve' and may fill out later. (I'm crossing my fingers on that one)

A side by side comparison for the RXB crew member vs the fine cast would be handy for most who don't know the model well.

As a Druchii player, the improvment is crystal clear.

I hope that this is a stepping stone to releasing new and amazing models. The Ushabti (spelling...) are fantastic looking, and I'm curious how they fare.

Again, thanks for the write up and step by step.

I have yet to pick up a finecast model, but I am interested to see what they are going to be like. I play Blood Angels though and have most of the characters already so there is not much I really need from the range and as such it will be awhile I pick any up.

ReplyDeleteThere are two things I am wondering about though. First what do you think they will be like for converting? I believe that they will be considerably easier then metal, but I have almost no experience with either conversions or resin, so I really have no idea. Is converting them something to be attempted by only the experienced modeler? Or can anyone have a go?

The second thing I am concerned about is the softness of the model. You mentioned in your review that were easily warped and I have read elsewhere that they are quite soft and weak. How does this bode for packing and transport? Do you have to be extremely delicate with them? How would they handle being dropped?